Please find my new (and old) posts at www.propagelleproject.com.

Monday, June 15, 2015

Wednesday, October 8, 2014

Block Making

We’ve had a great deal of welcome rain this summer. Everything is green and lush. I’m still waiting for the methane digester to turn all this grass to gas but you cannot push life (let alone work) in East Texas. We’re in a lovely Indian summer now with Fall-like days and cool mornings and bright sunshine, so we’ve picked up block making. Here’s how we do it—not how you should do it--but it may help you pay a little less tuition if you see what and understand WHY we do what we do.

We have stacked up 250 tons of clay and sand, which we mine with the tractor bucket. I dump 3 x 300lbs. of soil in 3 tractor buckets (10 x 5 gallon buckets each) of clay from the mound onto a hard floor where it is first tilled to a uniform blend, then I dump 100 pounds of Portland and mix it until the soil is a uniform color and properly damp—not wet.

I scoop up the prepared soil and dump it onto the screen above the hopper. Sometimes this requires a raking because of clods, which will not pass the required rock screen—catch a rock in the press, and it will bend the press. The large clods need to be recycled and smashed because they do not have cement inside them and so the blocks will be weak.

Once in the hopper, the fine dirt and cement falls onto the conveyor, which must be moving as you dump—this soil is heavy. The conveyor is connected to the hydraulic system in unison with the pressing pistons, so when any piston is under full load, the conveyor stops. When there is enough hydraulic pressure it resumes. We have identified the speed that keeps the press hopper loaded and thus continuously feeding the press but at the speed of the machine itself. The conveyor is perfect, and we are pleased at its contribution to the process. The hopper is also very slick and has never bridged. We are learning—slowly. Now we just need new bodies!

The blocks come out of the press and roll down a sloped conveyor where they are turned at a right angle two at a time, and they slide to the end of the second conveyor, ready to be off loaded onto the five pallets that hold about 100-120 blocks each. The blocks are first stacked nearly touching and standing on their narrow sides so that they can be watered completely—missing only the side that is down.

They get watered twice the first day to prevent surface cracking. Edges will break in the moving process, but that is no problem because the holes in the wall they leave act as “keys” and so we don’t have to make so many keys later. What you don’t want is surface cracking. They indicate differential drying inside the block.

You avoid surface cracking by thorough mixing of clay, sand and cement, then watering.

I broke one of the blocks made in the morning yesterday by hitting it in the middle with

a hammer. It cleaved properly and a close up reveals very uniform color, perfect fines distribution and a clean edge. The cracking inside came from the hammer blow.

The two of us can make around 200-300 blocks a day. We have to pick up and move 500 each day because yesterday’s batch must go to the construction site the first thing the next day. All the blocks are hauled by tractor to pallets near the construction site and re-laid. Each layer of blocks is first dampened—misted, not soaked. Then the second layer is laid across the first but flat too. The reason for changing the drying pattern of the entire stack is that it reduces the surface area presented to the air—thus less differential drying. When all 100 blocks on a pallet are stacked this way, the entire stack is misted and then shrink-wrapped around its sides. We cover the top with cut grass—of course! Watering must continue twice daily for 14 days until the cement is properly cured and extremely hard.

Two old people making blocks is exhausting, so we sit down a lot, drink electrolytes and enjoy the prospect of a strong, efficient and beautiful house. It doesn’t matter how many blocks we make...we have no worries! You can see the entire process set up in the last picture.

We have stacked up 250 tons of clay and sand, which we mine with the tractor bucket. I dump 3 x 300lbs. of soil in 3 tractor buckets (10 x 5 gallon buckets each) of clay from the mound onto a hard floor where it is first tilled to a uniform blend, then I dump 100 pounds of Portland and mix it until the soil is a uniform color and properly damp—not wet.

I scoop up the prepared soil and dump it onto the screen above the hopper. Sometimes this requires a raking because of clods, which will not pass the required rock screen—catch a rock in the press, and it will bend the press. The large clods need to be recycled and smashed because they do not have cement inside them and so the blocks will be weak.

Once in the hopper, the fine dirt and cement falls onto the conveyor, which must be moving as you dump—this soil is heavy. The conveyor is connected to the hydraulic system in unison with the pressing pistons, so when any piston is under full load, the conveyor stops. When there is enough hydraulic pressure it resumes. We have identified the speed that keeps the press hopper loaded and thus continuously feeding the press but at the speed of the machine itself. The conveyor is perfect, and we are pleased at its contribution to the process. The hopper is also very slick and has never bridged. We are learning—slowly. Now we just need new bodies!

The blocks come out of the press and roll down a sloped conveyor where they are turned at a right angle two at a time, and they slide to the end of the second conveyor, ready to be off loaded onto the five pallets that hold about 100-120 blocks each. The blocks are first stacked nearly touching and standing on their narrow sides so that they can be watered completely—missing only the side that is down.

They get watered twice the first day to prevent surface cracking. Edges will break in the moving process, but that is no problem because the holes in the wall they leave act as “keys” and so we don’t have to make so many keys later. What you don’t want is surface cracking. They indicate differential drying inside the block.

You avoid surface cracking by thorough mixing of clay, sand and cement, then watering.

I broke one of the blocks made in the morning yesterday by hitting it in the middle with

a hammer. It cleaved properly and a close up reveals very uniform color, perfect fines distribution and a clean edge. The cracking inside came from the hammer blow.

The two of us can make around 200-300 blocks a day. We have to pick up and move 500 each day because yesterday’s batch must go to the construction site the first thing the next day. All the blocks are hauled by tractor to pallets near the construction site and re-laid. Each layer of blocks is first dampened—misted, not soaked. Then the second layer is laid across the first but flat too. The reason for changing the drying pattern of the entire stack is that it reduces the surface area presented to the air—thus less differential drying. When all 100 blocks on a pallet are stacked this way, the entire stack is misted and then shrink-wrapped around its sides. We cover the top with cut grass—of course! Watering must continue twice daily for 14 days until the cement is properly cured and extremely hard.

Two old people making blocks is exhausting, so we sit down a lot, drink electrolytes and enjoy the prospect of a strong, efficient and beautiful house. It doesn’t matter how many blocks we make...we have no worries! You can see the entire process set up in the last picture.

Tuesday, August 5, 2014

Methane in Context

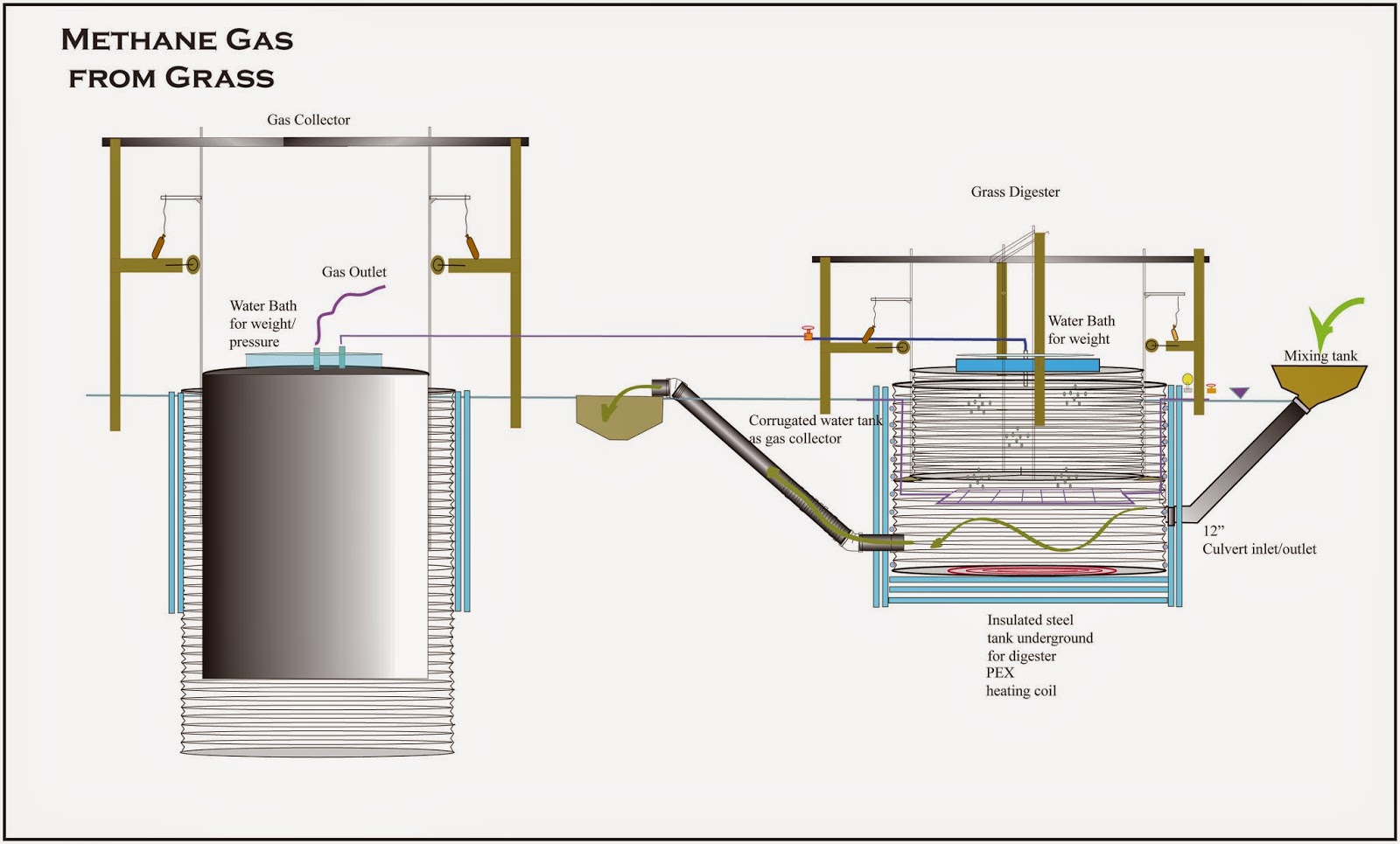

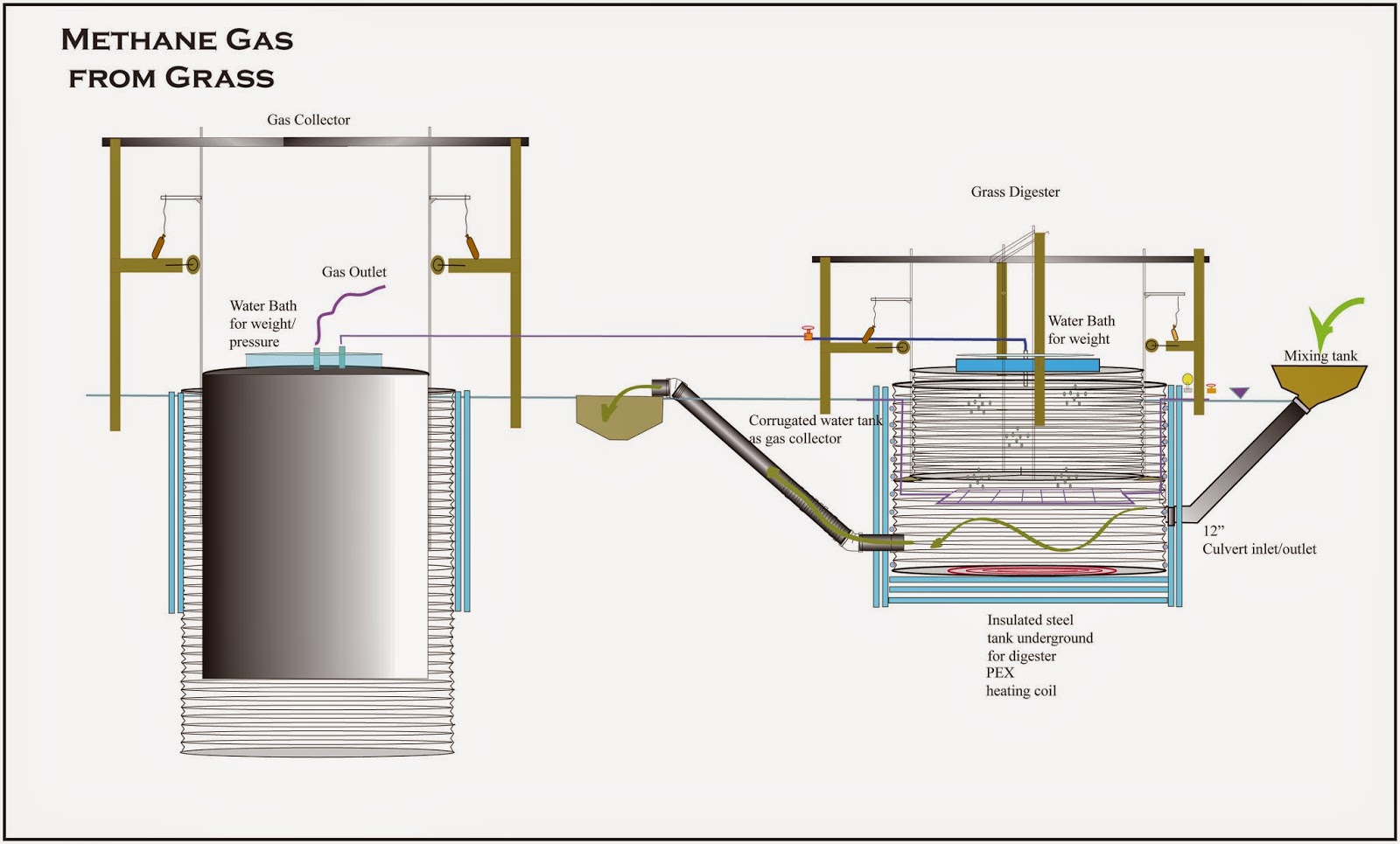

Methane production by itself is a fascinating and exciting subject both

as theory and design. Now it’s time to build and install one. I think it

might be hard to see how I am integrating methane with the CEB house,

so I thought I would post a bit of a site plan and then add a more

detailed drawing of the power-house or engine room.

In due time each of the features noted in the site plan will be discussed from solar array installation to anaerobic drip irrigation and fruit tree fertigation, to name a few.

Every feature and component in this master-planned, 10 acre system is intended to bring us closer to complete import substitution of food and energy via a regenerative ecosystem so that productivity continues to rise (until natural climax conditions obtain) but inputs, maintenance and pollution decrease as time passes.

In case you don’t understand the significance of that statement, consider the fact that any de-generative system will require increasing inputs and pollution to sustain productivity and eventually just fall apart from exhaustion—not because resources are not available, but because you cannot afford to get them to your site and keep it all running.

Here is a drawing of my CEB house and site plan to give you a perspective of where and how the methane system is integrated with it all. The next drawing is a close-up of the powerhouse and some of its features.

Don’t get too bent out of shape that the engine is inside the power shed. The engine is similar to the ones you did not know were gas powered engines such as run the floor cleaners in the big box stores—fitted with special exhaust systems, fumes collection and noise dampening technology. They come set for either Propane or NG and so will not require any adjustment to run on my clean methane. The battery boxes are sealed and power vented, so no hydrogen will escape to the room either. There’s lots of other safety features, but this will do for today.

In due time each of the features noted in the site plan will be discussed from solar array installation to anaerobic drip irrigation and fruit tree fertigation, to name a few.

Every feature and component in this master-planned, 10 acre system is intended to bring us closer to complete import substitution of food and energy via a regenerative ecosystem so that productivity continues to rise (until natural climax conditions obtain) but inputs, maintenance and pollution decrease as time passes.

In case you don’t understand the significance of that statement, consider the fact that any de-generative system will require increasing inputs and pollution to sustain productivity and eventually just fall apart from exhaustion—not because resources are not available, but because you cannot afford to get them to your site and keep it all running.

Here is a drawing of my CEB house and site plan to give you a perspective of where and how the methane system is integrated with it all. The next drawing is a close-up of the powerhouse and some of its features.

Don’t get too bent out of shape that the engine is inside the power shed. The engine is similar to the ones you did not know were gas powered engines such as run the floor cleaners in the big box stores—fitted with special exhaust systems, fumes collection and noise dampening technology. They come set for either Propane or NG and so will not require any adjustment to run on my clean methane. The battery boxes are sealed and power vented, so no hydrogen will escape to the room either. There’s lots of other safety features, but this will do for today.

Sunday, August 3, 2014

Methane Dreams

A thoughtful and kind reader of my last blog, “Let there be light,” wrote to question my methane dream of a free lunch and the “math” I used to obtain it. I normally don’t respond to comments except that other readers of the comment might be discouraged by the markedly reduced gas production our anonymous commentator suggested was more realistic—based on different assumptions and the logical conclusions that follow...and a bias to gasification technology, it seems. We are on the same side in the end, just exchanging clarifying assumptions to support our different dreams.

The mistake in the reader's response/comment was the assumption that Volatile Solids (Vs) in grass is equal to the dry matter portion of the grass. The Chinese biogas manual published in 1976 (which I assume he used as a reference and which I really like and use myself, especially for how to make brick domes--bovidas!) says that 1 ton of dry grass can produce X volume of methane over 30 days. Since wet grass is mostly water, it would seem to make sense that you’d need a lot more wet grass to equal 1 ton of dry matter to get your big lunch of methane. But, it’s more complicated than that.

What happens when you dry grass is that the actual Vs fraction is seriously reduced—maybe by half. And, if the grass was low quality (no protein) to begin with, then you will get even less methane from it. Further, the dry grass equation was typically derived from feeding the dry grass/hay substrate to cattle and using the cow dung as the feedstock for the methane potential. And that is where the formula/critique really runs amok. The Vs potential from cow dung is typically about 1/10th. Strange as it may seem, cow dung is not the best substrate for methane production (1 lb. of poop evolves somewhere between 1.5 to max. 5 ft3 Humanure/sewer sludge produces even less. The reason cow dung (gobar in India) isn’t as productive as fresh grass is that the cellulose (primary methane substrate) in cow dung is significantly reduced due to its loss through digestion by anaerobic bacteria in the rumen.

So that brings us back to grass—fresh, wet fertilized grass, like Coastal Bermuda, or any grass with protein over 10%. What’s the Vs/CH4 potential for such grasses? Not 5 ft3 optimal for cow dung, but 10.7ft3 per pound of fresh, green grass. Now that assumes that all other factors for methane production are ideal—heat, additional water and stirring so the bacteria get everything they need to make gas with every tiny bite they take. You can study the easy to follow design theory by Peter-John Meynell (I think he’s the world’s leading practitioner and thus my authority) and the highly technical studies by CRS press on methane production if you want further confidence on this matter. Pick your poison.

While I’m at it, let me address one other typical “problem” that methane junkies make a big deal out of that need not obtain with grass methanogenesis. If you’ve read the literature at all, you know that the production of methane is a “two-stage” process in which the substrate is initially digested by acidifiers (anaerobic bacteria), which produce an acid substrate that the methanogens love and consume at high rates. They stuff themselves, then go to bed, reproduce and pass gas. (Confirms humans are, in fact, evolved from such lower life forms!) The higher the temperature, the more they reproduce and make gas! Nice life!

Given that process, say the purists, you have to design and run a two-stage (bloody expensive) digester or the Darwinian acidifiers will overwhelm the weaker methanogens and the whole mess will stop until the two sides come to terms. And the two will indeed settle down and get back to normal life and good methane production.

One final note about this two-stage process the purists push on us. Remember the cow stomach model? If you feed the digester like you should feed your cow, then it will not get “acidosis” and overwhelm (inhibit) methanogens from doing their thing. Cows manage this, so I figure we can to. How? Notice your cow. It eats twice a day and lies down to chew the cud. A standing cow is a hungry or an upset cow. We will therefore feed our cow/digester twice a day with 50 pounds in the morning (saved from the previous day’s cutting) and 50 pounds in the evening and always within an hour of the scheduled time—exactly like you feed and milk a cow. The slug of grass goes in, excites the acidifiers who go right to work and then run out of food/grass and the methanogens take over. Before the acidifiers start to die off, you feed them again, and throughout the night they stay happy (the digester will cool down somewhat and slow the process nicely) until breakfast in the morning. You can put the digester “stomach” on a schedule just like a cow—the more regular, the more gas you’ll get. My model digester will always stop making methane whenever I overload it to show off “the big flush” for guests and then slack off loading it, but it will sort itself out and get back to work and, then, suddenly a whole lot of gas bubbles up and we are back in business.

In the end, the numbers (from whatever authority one picks—they’re not on the internet!) are just a guide and give us light to suggest a way forward with hope. What we need is a working, full-scale system that is integrated into a regenerative landscape. Only then will we see what grass can actually do. Watch this Blog for the construction, installation and operation of my design for methane production from cut grass on my off-grid,10-acre homestead. I’ll post photos and a running commentary. Hopefully this digester project will get done this summer while we have grass and heat.

Mine is a methane dream. I know nothing of gasification other than a few desktop designs I’ve done for Africa and some US parks with trash trees to use as sustainable biomass sources. I think the correct order for the use of gasification where I live is: make methane first, dry the sludge, and gasify that. You have only ash to dispose of at that point. Not good for me. I value the sludge for growing more grass as much as the methane it will produce.

I believe that in this bio-region, methane from fresh grass is an under-utilized, regenerative resource for maintaining a modest, self-reliant, rural life and an independent community that such a lifestyle will not only support but require.

Dream on!

The mistake in the reader's response/comment was the assumption that Volatile Solids (Vs) in grass is equal to the dry matter portion of the grass. The Chinese biogas manual published in 1976 (which I assume he used as a reference and which I really like and use myself, especially for how to make brick domes--bovidas!) says that 1 ton of dry grass can produce X volume of methane over 30 days. Since wet grass is mostly water, it would seem to make sense that you’d need a lot more wet grass to equal 1 ton of dry matter to get your big lunch of methane. But, it’s more complicated than that.

What happens when you dry grass is that the actual Vs fraction is seriously reduced—maybe by half. And, if the grass was low quality (no protein) to begin with, then you will get even less methane from it. Further, the dry grass equation was typically derived from feeding the dry grass/hay substrate to cattle and using the cow dung as the feedstock for the methane potential. And that is where the formula/critique really runs amok. The Vs potential from cow dung is typically about 1/10th. Strange as it may seem, cow dung is not the best substrate for methane production (1 lb. of poop evolves somewhere between 1.5 to max. 5 ft3 Humanure/sewer sludge produces even less. The reason cow dung (gobar in India) isn’t as productive as fresh grass is that the cellulose (primary methane substrate) in cow dung is significantly reduced due to its loss through digestion by anaerobic bacteria in the rumen.

So that brings us back to grass—fresh, wet fertilized grass, like Coastal Bermuda, or any grass with protein over 10%. What’s the Vs/CH4 potential for such grasses? Not 5 ft3 optimal for cow dung, but 10.7ft3 per pound of fresh, green grass. Now that assumes that all other factors for methane production are ideal—heat, additional water and stirring so the bacteria get everything they need to make gas with every tiny bite they take. You can study the easy to follow design theory by Peter-John Meynell (I think he’s the world’s leading practitioner and thus my authority) and the highly technical studies by CRS press on methane production if you want further confidence on this matter. Pick your poison.

While I’m at it, let me address one other typical “problem” that methane junkies make a big deal out of that need not obtain with grass methanogenesis. If you’ve read the literature at all, you know that the production of methane is a “two-stage” process in which the substrate is initially digested by acidifiers (anaerobic bacteria), which produce an acid substrate that the methanogens love and consume at high rates. They stuff themselves, then go to bed, reproduce and pass gas. (Confirms humans are, in fact, evolved from such lower life forms!) The higher the temperature, the more they reproduce and make gas! Nice life!

Given that process, say the purists, you have to design and run a two-stage (bloody expensive) digester or the Darwinian acidifiers will overwhelm the weaker methanogens and the whole mess will stop until the two sides come to terms. And the two will indeed settle down and get back to normal life and good methane production.

One final note about this two-stage process the purists push on us. Remember the cow stomach model? If you feed the digester like you should feed your cow, then it will not get “acidosis” and overwhelm (inhibit) methanogens from doing their thing. Cows manage this, so I figure we can to. How? Notice your cow. It eats twice a day and lies down to chew the cud. A standing cow is a hungry or an upset cow. We will therefore feed our cow/digester twice a day with 50 pounds in the morning (saved from the previous day’s cutting) and 50 pounds in the evening and always within an hour of the scheduled time—exactly like you feed and milk a cow. The slug of grass goes in, excites the acidifiers who go right to work and then run out of food/grass and the methanogens take over. Before the acidifiers start to die off, you feed them again, and throughout the night they stay happy (the digester will cool down somewhat and slow the process nicely) until breakfast in the morning. You can put the digester “stomach” on a schedule just like a cow—the more regular, the more gas you’ll get. My model digester will always stop making methane whenever I overload it to show off “the big flush” for guests and then slack off loading it, but it will sort itself out and get back to work and, then, suddenly a whole lot of gas bubbles up and we are back in business.

In the end, the numbers (from whatever authority one picks—they’re not on the internet!) are just a guide and give us light to suggest a way forward with hope. What we need is a working, full-scale system that is integrated into a regenerative landscape. Only then will we see what grass can actually do. Watch this Blog for the construction, installation and operation of my design for methane production from cut grass on my off-grid,10-acre homestead. I’ll post photos and a running commentary. Hopefully this digester project will get done this summer while we have grass and heat.

Mine is a methane dream. I know nothing of gasification other than a few desktop designs I’ve done for Africa and some US parks with trash trees to use as sustainable biomass sources. I think the correct order for the use of gasification where I live is: make methane first, dry the sludge, and gasify that. You have only ash to dispose of at that point. Not good for me. I value the sludge for growing more grass as much as the methane it will produce.

I believe that in this bio-region, methane from fresh grass is an under-utilized, regenerative resource for maintaining a modest, self-reliant, rural life and an independent community that such a lifestyle will not only support but require.

Dream on!

Wednesday, July 30, 2014

Let There Be Light

Methane from grass

clippings has been happening on my farm for the last 9 years. You can see an

earlier post of the experimental system. Interest is finally picking up, even

though few believe the hot, blue flame on the stove is methane when they see

it.

Fiat lux!

Fiat lux!

I thought it might be helpful to run some numbers passed the

unwashed on this subject. Costs per kilowatt of electricity in Texas are fixin’

to rise. There’s no real reason just now to hike the cost since they’ve been

pumping out methyl-mercury, cadmium, lead, and arsenic, to say nothing of CO2,

from our coal fired power plants with impunity for decades in spite of EPA

“regulations” and threats and even fines! Well, actually, maybe there is ONE

reason. It’s an election year; and hurting the masses is how to make sure the

little people understand the “costs” of supporting the wrong politicians! (see

Gaza today for a global example of this “civilized” policy! What Geneva

conventions?!)

All that to say, I imagine alternative energy is about to

become a serious business. Which will, ironically, make the price of a kilowatt

go even higher for the poor! I’ll punt here on the equality subject and move on

to methane in hopes we can avoid re-inventing the wheel on alternative energy

from biomass. Methane from grass has been done! Experimental, table top scale

digesters are a dime a dozen.

Here’s what I know, and feel confident printing for the

serious methane producer. You’ve got to figure two things—supply and demand. The

math for both must be done first, then the technology for how to realize the

math follows—not the other way around, guys!

Calculations for demand

and how to supply that demand

are as follows:

Obviously we have to start with what volume of Methane (CH4)

we can reasonably expect to make given our various resources and labor. Then we

must cut demand down as much as possible to either meet the limits of supply or

have a surplus--if we’re lucky. We (in this county) cannot sell surplus

kilowatts back to our cooperative. Nowhere is it worth it economically (if you

care about life-cycle costs) to deliberately plan to make a surplus. It just

leads to waste.

Potential supply:

Methane production is a function of the right ratio of

feedstock (cow dung or finely cut fertilized grass at around 25:1 C:N ratio) to

water and heat on a daily basis. Think a cow stomach and flatulence, and you

get the idea.

In East Texas, we have massive amounts of daily sunlight

that produce equally massive amounts of fresh, high protein (where the N comes

from) grass. This grass, when finely cut, is ideal for methane production. It

has about a 25:1 carbon-nitrogen ratio and that is actually better than

cow-dung. There is much less work (energy) involved in mowing the grass and

vacuuming up the mulched material than collecting dung in buckets, or even in

troughs under feeding stations and pumping it to a digester with slurry pumps.

I won’t launch into the “embodied energy” debate over the

energy “mass balance” of our grass conversion, but, trust me, it is in my favor

to use gasoline to cut the grass to produce methane to produce electricity.

It’s almost a free lunch! Far better conversion efficiency than bio-diesel!

Wait till I run my mower on compressed methane!

Given our rainfall and sunlight, we can easily collect

100-300 pounds of finely cut grass every day for about 200 days a year. The

other165 we will need to have a supply of this same grass made into silage and stored for the digester and a

little extra for the cows during winter.

Let’s say we cut 100 pounds of rich green grass each day for

the 200 days of growing grass for the digester. How much methane gas (scrubbed

of sulfur and carbon dioxide to burn @ 900 btus’ a cubic foot) can we make from

100 pounds of fresh, wet, fertilized Coastal Bermuda?

The rule of thumb in this business (for the 40 years I’ve

played around with this gas) is that 2000 pounds (1 ton) of fresh grass can

produce 630 cubic meters (that’s meters)

of gas over a 30-day period if the temperature stays around 1000F.

We can convert meters to cubic feet @ a ratio of 35ft3 of methane

for every cubic meter produced. Translation: For every ton of grass, we can

expect 22,000 ft3 of methane (CH4) over a 30-day

digestion period with stable heat. That’s 733ft3 per day of useful

methane. (22,000/30=733)

That means that for every pound of grass we insert in the

digester, we can expect about 10ft3 of methane. (22,000/2000). If we

cut and deposit 100 pounds of grass a day, we can thus expect 1000 ft3

of CH4 in 24 hours time—all other things being proper.

Demand side:

How much gas will we need, and how much grass must we then

cut and haul to the digester each day to make the gas we need?

In the gas business, a rule of thumb has been that one

cubic meter of

methane (900-1000 btus) will power a 1 horse-power engine under load for 2

hours. Put another way, for every horsepower you use, you must supply 17ft3

of scrubbed CH4 per hour.

Our 16kW propane/NG stand-by generator requires a 24 hp

engine, so we must have 275ft3 of methane each hour of run time.

Remember, 100 pounds of grass will give us 1000ft3 of CH4

a day, so we can run our generator each day for 3.5 hours on 100 pounds of

grass. That’s enough to power the peak hours demand and charge the batteries.

If we got all the gas we theoretically could get, we would produce 58 kilowatts

a day. De-rate that by 15% for lots of reasons and you still have more than you

need—or should use. Logically you would size the digester and grass collection

to meet your actual demand--less than 30 kW a day, I should hope. This desktop

design gets you close to that with some surplus for cooking.

Sizing the Digester

We will plan for a digester (cow stomach) that can hold 100

pounds of cut grass (and enough water to make a slurry so it flushes down the

inlet pipe like a toilet) for 30 days total volume. We call this digester

design a plug-flow digester with a 30-day detention time. 100 pounds of grass will

need between 80 to100 gallons of water a day, so the digester must hold about

3000 gallons of slurry to start.

Every day 100 gallons of extremely valuable fertilizer and

water will be excreted from the digester to a holding tank as it is “displaced”

by the incoming fresh slug of material. This must go back on the grass

production area to make the system truly regenerative!

An “intake” mixing basin with a water hose nearby and an

easy plug or valve will allow the grass and water to be mixed as the grass is

dumped into the mixer at ground level from the lawn vacuum thus requiring no

human labor to load the biomass. When the grass is covered with water, the plug

is pulled and the entire slurry slug swirls down the inlet pipe with a giant

sucking sound into the bowels of the digester. This flush stirs the rest of the

rotting mess and keeps the surface from matting over with tiny bits of material

that could end up forming a paper-like crust and closing down gas production. The larger the surface area of the

digester, the less likely this crust will form—so short and fat is better than

deep and skinny for the tanks. The opposite is true for gas holding and

pressure tanks.

Stirring beyond the daily intake disturbance is not usually

needed, but it can easily be done by mounting a series of 1 inch diameter

galvanized pipes with 1/8th in. holes on the under side so that gas

under pressure from the holding tank can be introduced into the digester tank

to stir the slurry and break up surface scum. This gas immediately returns to

the gasholder from whence it came. A separate gasholder set of tanks is required

for large methane systems, but more of that later. The diagram included here

shows the basic design of my 3000 gallon system.

The digester needs both an inlet and an outlet of 10- 12

inches in diameter (I use a culvert with rough ridges outside and smooth liner

inside) to make flushing easy and quick.

The entire system water level is set by the invert of the

outlet pipe, so that must be done carefully. I like my tanks underground and insulated

to stay warm and at even temperatures year round. The grass around both tanks

looks neat and green, and it is easy to keep it trimmed.

These are some of the bare minimum details and basic

calculations to give you the idea that methane in areas of good sunlight and

rainfall is certainly a viable way of producing useful gas for cooking and

electricity in place of propane or natural gas.

A few diagrams and calculations will follow with another

narrative later so you can see how to size the various components of the entire

system, which includes safe methane delivery to the engine and a whole lot of

other safety stuff.

If your life and landscaping is not purpose driven yet, now it can be--mow to turn grass into methane

gas!

Thursday, June 12, 2014

The Conveyor Unveiled and On-site

We had a brief scare with fracking this week, but we are moving on now.

The new conveyor is a great piece of machinery that works as beautifully

as it looks. I took this picture as we hurried to finish setting it up

enough to survive one of our many storms these days.

Testing in the field now begins as it emerges from the shop and links the dirt processing to the block pressing. It will also be used to lift blocks up to the scaffold later and maybe even haul cement to the bond beam. Who knows what all it can be used for right now.

What is clear is that it meets all the original criteria for its design and use. It must:

I think it meets all of these criteria and does so elegantly!

Here are some close-up shots of various parts of the machine to give you some idea of how it was built and how it works.

Testing in the field now begins as it emerges from the shop and links the dirt processing to the block pressing. It will also be used to lift blocks up to the scaffold later and maybe even haul cement to the bond beam. Who knows what all it can be used for right now.

What is clear is that it meets all the original criteria for its design and use. It must:

- be light and easy to move around.

- be easy to get the height set exactly and not have it to move or drop under weight.

- be made of local materials and use either old carpet or old belts (possibly truck tire tubes patched together in Africa) for the conveyor.

- be easy to turn so that the hydraulic demand to turn it does not slow the block making process by drawing of fluid from the other two pistons.

- “marry” to the hopper easily and without spilling too much dirt as it turns under the hopper door.

- be very quiet and safe to stand near.

- be weather –proof.

I think it meets all of these criteria and does so elegantly!

Here are some close-up shots of various parts of the machine to give you some idea of how it was built and how it works.

|

| On site setting up with a side view of the hopper frame and block press with the 12 ft long conveyor between |

|

| Lashed down for storm survival. |

|

| The stitching seam and 20-inch wide PVC carpet belt. |

Stay of Execution

Today we got some very good news. We

posted our refusal letter (copied below) and then discovered that two of

the big land owners in the "pool" also rejected the offer. We have

had a stay of execution. The bad news is that another company is nosing

around, so we may go through this again. We will be better prepared

this time, however, because we have had time to find some legal help and

will keep our wits about us a little better...maybe!

Today we got some very good news. We

posted our refusal letter (copied below) and then discovered that two of

the big land owners in the "pool" also rejected the offer. We have

had a stay of execution. The bad news is that another company is nosing

around, so we may go through this again. We will be better prepared

this time, however, because we have had time to find some legal help and

will keep our wits about us a little better...maybe!

Our

biggest problem today is what to do with the excessive fruit harvest.

We'll pick it all and take it to the senior center. Mind boggling how

much surplus a happy tree can produce!

Ironwill letter of rejection

Dear ____________,

We are in receipt of your offer on behalf of _________Energy,

LLC. We understand that our reply was to be in your hand by June 13, 2014.

Herewith our reply:

1. We live on a small property which is intensely designed

and built to produce our own food, water and energy as we have retired on a

fixed income. Our goal is precisely to reduce our carbon footprint so as to

obviate the need for your production of fossil fuels. The irony of your

intentions and our objectives is not lost on us.

2.We understand all too well that we do not have controlling

ownership of the minerals underneath our property and that _______ Oil and its

subsidiary contractors may do whatever they wish to obtain their leased product

under our land—including drilling a water well and withdrawing (and potentially

polluting) millions of gallons of fresh water from the aquifer we now depend

on.

3. We are especially dependent on our shallow well. We will

be required to begin monitoring it monthly now for a full year to establish a

“baseline” of quality that we fear will be compromised by nearby “fracking.”

After reading the terrifying accounts of toxic waste and negligence in Wise

County recently, we are doubly concerned that our well (as well as our

aquaculture ponds) will be contaminated with hydrocarbons such as toluene and

benzene. If we hire an independent lab, the fee the nearest lab quoted us for

one test of one sample for Benzene alone is $600. We need 12 of those for a

baseline and then at least three (3) years of testing after you begin

production. Chain of custody requires them to travel and sample themselves.

Exceedence of the published EPA standard for each pollutant would be the

deciding line for redress by _______ Oil after a year of monitoring. Your contract

requires us to bear this burden of expense. You can do the math. Your current

offer would not even pay for testing, let alone a new well or mitigation of the

existing one.

4. We have read your pro-forma lease with its terms

decidedly in favor of _______ Oil and against us as small landowners. To our

surprise we have been asked to sign a non-disclosure contract BEFORE we know

the terms of the “final” contract. ______ Oil can and will proceed to do whatever

disturbance and property damage they wish with or without or signatures. Our

only chance for redress, unless you re-write the contract more fairly, is in

the court of public opinion. We therefore cannot sign the confidentiality

agreement at this time.

5. We, however, would like to plead with you and your

clients to consider our situation and re-draft your offer and conditions to

better protect our life-long investment and our future retirement on this tiny

property. We respectfully request that you include a clause that will promise us

that no drilling of any kind will occur on our eleven (11) acres and that you

will not create or maintain drilling or storage pits and no pipeline will cross

or enter our property during the period of this lease.

6. With regard to your initial offer of prepayment (your

point #2 “purchase price”) for the lease of surface property (based as it is on

a per-acre sum), we ask you to consider that any activity by _______ Oil on this

small property will do disproportionately greater damage than on the neighbors’

holdings due to the fact that they own large tracts and are absentee landlords who do not live here. They are able to retain

legal counsel and have resources to seek redress. We cannot. Unless this

contract reflects our particular burdens up-front, we will not be able to

mitigate any damage, let alone sue for damages. Our only recourse (should you

refuse our requests) will be to walk away from our Life-Place after investing

over 20 years of work and almost a half million dollars in structures and

research to live off-grid and within our fixed Social Security income. We have

no alternative place to move to or to begin again, even if we had the resources

to do so. We feel morally (one human being to another) obliged to ask you to

represent our concerns to your clients.

7. We hereby request a modified and more fair contract offer

from you. We have not had enough to time to obtain legal (necessarily pro-bono)

counsel on this matter, so we are beholden to you for any misspoken words or

delays due to our ignorance. We respect the rights of _______ Oil under current

Texas Law to obtain the product below and “severed” from our surface property.

Rest assured, we will not intentionally interfere or delay their plans to

obtain said product. We would like to know when they plan to begin surveying

and then drilling as soon as these plans are available.

We trust that you will give our particular situation due

consideration and re-write a contract in a timely manner that reflects our

concerns and limited resources.

Subscribe to:

Comments (Atom)