I thought it might be helpful to run some numbers passed the

unwashed on this subject. Costs per kilowatt of electricity in Texas are fixin’

to rise. There’s no real reason just now to hike the cost since they’ve been

pumping out methyl-mercury, cadmium, lead, and arsenic, to say nothing of CO2,

from our coal fired power plants with impunity for decades in spite of EPA

“regulations” and threats and even fines! Well, actually, maybe there is ONE

reason. It’s an election year; and hurting the masses is how to make sure the

little people understand the “costs” of supporting the wrong politicians! (see

Gaza today for a global example of this “civilized” policy! What Geneva

conventions?!)

All that to say, I imagine alternative energy is about to

become a serious business. Which will, ironically, make the price of a kilowatt

go even higher for the poor! I’ll punt here on the equality subject and move on

to methane in hopes we can avoid re-inventing the wheel on alternative energy

from biomass. Methane from grass has been done! Experimental, table top scale

digesters are a dime a dozen.

Here’s what I know, and feel confident printing for the

serious methane producer. You’ve got to figure two things—supply and demand. The

math for both must be done first, then the technology for how to realize the

math follows—not the other way around, guys!

Calculations for demand

and how to supply that demand

are as follows:

Obviously we have to start with what volume of Methane (CH4)

we can reasonably expect to make given our various resources and labor. Then we

must cut demand down as much as possible to either meet the limits of supply or

have a surplus--if we’re lucky. We (in this county) cannot sell surplus

kilowatts back to our cooperative. Nowhere is it worth it economically (if you

care about life-cycle costs) to deliberately plan to make a surplus. It just

leads to waste.

Potential supply:

Methane production is a function of the right ratio of

feedstock (cow dung or finely cut fertilized grass at around 25:1 C:N ratio) to

water and heat on a daily basis. Think a cow stomach and flatulence, and you

get the idea.

In East Texas, we have massive amounts of daily sunlight

that produce equally massive amounts of fresh, high protein (where the N comes

from) grass. This grass, when finely cut, is ideal for methane production. It

has about a 25:1 carbon-nitrogen ratio and that is actually better than

cow-dung. There is much less work (energy) involved in mowing the grass and

vacuuming up the mulched material than collecting dung in buckets, or even in

troughs under feeding stations and pumping it to a digester with slurry pumps.

I won’t launch into the “embodied energy” debate over the

energy “mass balance” of our grass conversion, but, trust me, it is in my favor

to use gasoline to cut the grass to produce methane to produce electricity.

It’s almost a free lunch! Far better conversion efficiency than bio-diesel!

Wait till I run my mower on compressed methane!

Given our rainfall and sunlight, we can easily collect

100-300 pounds of finely cut grass every day for about 200 days a year. The

other165 we will need to have a supply of this same grass made into silage and stored for the digester and a

little extra for the cows during winter.

Let’s say we cut 100 pounds of rich green grass each day for

the 200 days of growing grass for the digester. How much methane gas (scrubbed

of sulfur and carbon dioxide to burn @ 900 btus’ a cubic foot) can we make from

100 pounds of fresh, wet, fertilized Coastal Bermuda?

The rule of thumb in this business (for the 40 years I’ve

played around with this gas) is that 2000 pounds (1 ton) of fresh grass can

produce 630 cubic meters (that’s meters)

of gas over a 30-day period if the temperature stays around 1000F.

We can convert meters to cubic feet @ a ratio of 35ft3 of methane

for every cubic meter produced. Translation: For every ton of grass, we can

expect 22,000 ft3 of methane (CH4) over a 30-day

digestion period with stable heat. That’s 733ft3 per day of useful

methane. (22,000/30=733)

That means that for every pound of grass we insert in the

digester, we can expect about 10ft3 of methane. (22,000/2000). If we

cut and deposit 100 pounds of grass a day, we can thus expect 1000 ft3

of CH4 in 24 hours time—all other things being proper.

Demand side:

How much gas will we need, and how much grass must we then

cut and haul to the digester each day to make the gas we need?

In the gas business, a rule of thumb has been that one

cubic meter of

methane (900-1000 btus) will power a 1 horse-power engine under load for 2

hours. Put another way, for every horsepower you use, you must supply 17ft3

of scrubbed CH4 per hour.

Our 16kW propane/NG stand-by generator requires a 24 hp

engine, so we must have 275ft3 of methane each hour of run time.

Remember, 100 pounds of grass will give us 1000ft3 of CH4

a day, so we can run our generator each day for 3.5 hours on 100 pounds of

grass. That’s enough to power the peak hours demand and charge the batteries.

If we got all the gas we theoretically could get, we would produce 58 kilowatts

a day. De-rate that by 15% for lots of reasons and you still have more than you

need—or should use. Logically you would size the digester and grass collection

to meet your actual demand--less than 30 kW a day, I should hope. This desktop

design gets you close to that with some surplus for cooking.

Sizing the Digester

We will plan for a digester (cow stomach) that can hold 100

pounds of cut grass (and enough water to make a slurry so it flushes down the

inlet pipe like a toilet) for 30 days total volume. We call this digester

design a plug-flow digester with a 30-day detention time. 100 pounds of grass will

need between 80 to100 gallons of water a day, so the digester must hold about

3000 gallons of slurry to start.

Every day 100 gallons of extremely valuable fertilizer and

water will be excreted from the digester to a holding tank as it is “displaced”

by the incoming fresh slug of material. This must go back on the grass

production area to make the system truly regenerative!

An “intake” mixing basin with a water hose nearby and an

easy plug or valve will allow the grass and water to be mixed as the grass is

dumped into the mixer at ground level from the lawn vacuum thus requiring no

human labor to load the biomass. When the grass is covered with water, the plug

is pulled and the entire slurry slug swirls down the inlet pipe with a giant

sucking sound into the bowels of the digester. This flush stirs the rest of the

rotting mess and keeps the surface from matting over with tiny bits of material

that could end up forming a paper-like crust and closing down gas production. The larger the surface area of the

digester, the less likely this crust will form—so short and fat is better than

deep and skinny for the tanks. The opposite is true for gas holding and

pressure tanks.

Stirring beyond the daily intake disturbance is not usually

needed, but it can easily be done by mounting a series of 1 inch diameter

galvanized pipes with 1/8th in. holes on the under side so that gas

under pressure from the holding tank can be introduced into the digester tank

to stir the slurry and break up surface scum. This gas immediately returns to

the gasholder from whence it came. A separate gasholder set of tanks is required

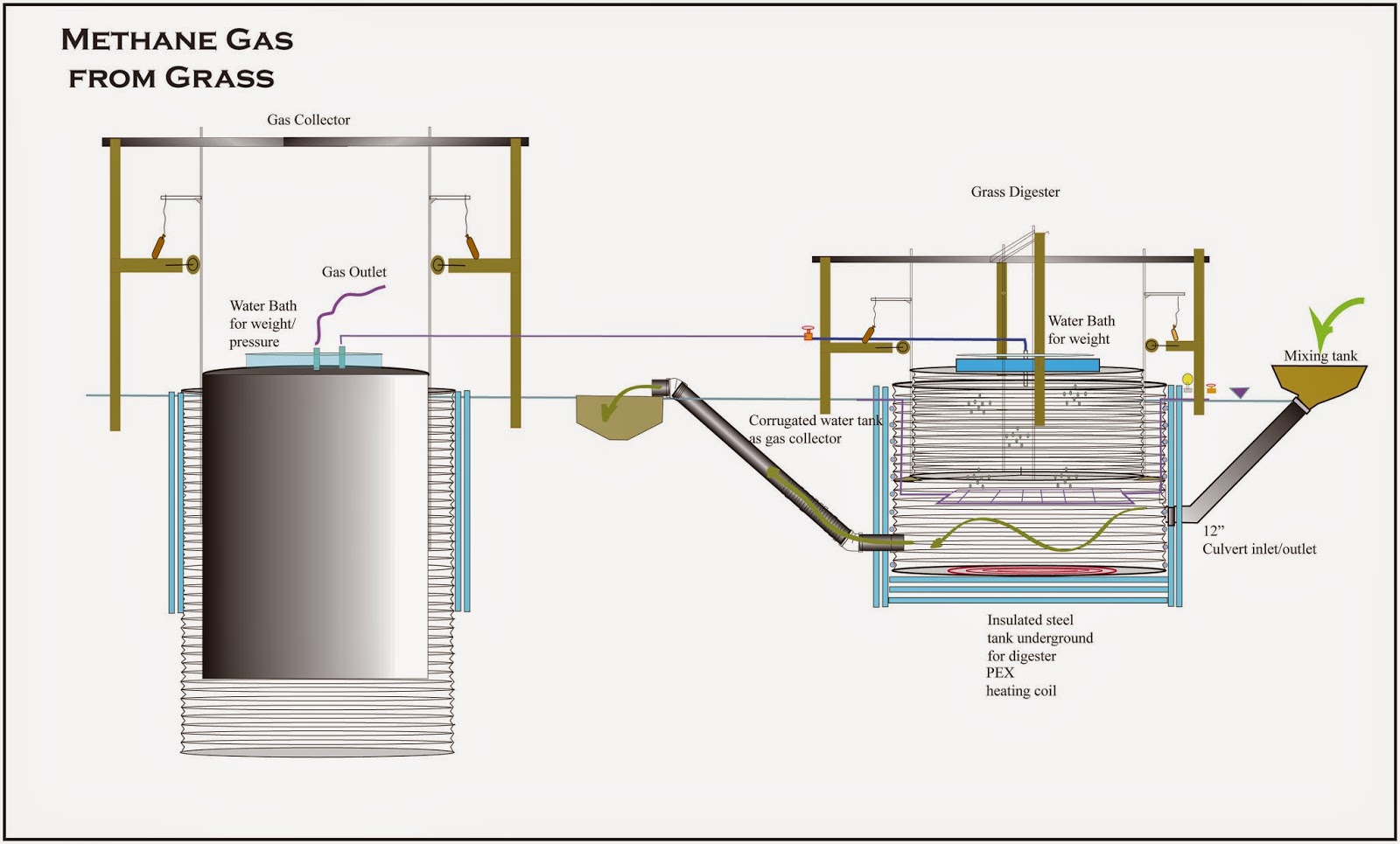

for large methane systems, but more of that later. The diagram included here

shows the basic design of my 3000 gallon system.

The digester needs both an inlet and an outlet of 10- 12

inches in diameter (I use a culvert with rough ridges outside and smooth liner

inside) to make flushing easy and quick.

The entire system water level is set by the invert of the

outlet pipe, so that must be done carefully. I like my tanks underground and insulated

to stay warm and at even temperatures year round. The grass around both tanks

looks neat and green, and it is easy to keep it trimmed.

These are some of the bare minimum details and basic

calculations to give you the idea that methane in areas of good sunlight and

rainfall is certainly a viable way of producing useful gas for cooking and

electricity in place of propane or natural gas.

A few diagrams and calculations will follow with another

narrative later so you can see how to size the various components of the entire

system, which includes safe methane delivery to the engine and a whole lot of

other safety stuff.

If your life and landscaping is not purpose driven yet, now it can be--mow to turn grass into methane

gas!

2 comments:

According to Wikipedia, Methane has 1000 btu per CUBIC FOOT, not cubic meter. http://en.wikipedia.org/wiki/Methane

Also, you may want to check your math, because 100 lbs of fresh grass only really equals about 10-20lbs of dry matter, which has a btu value of about 8,000 btu/lb. The maximum btu that 100 lbs of grass could produce would be about 160,000 btu.

You claim we can produce 1000 ft3 per 100 lbs of fresh grass, which would yield 1,000,000 btu. There's obviously something amiss here, because the grass doesn't contain that much energy to begin with, and conversion to methane will never be 100% efficient.

I imagine the yield is closer to 80 cubic feet of actual methane per 100lbs of fresh grass.

You may also consider drying the grass and then running a gasifier to power a generator. Overall, your efficiency will be higher (gasification exceeds biodigester in efficiency), and you can store your dry fuel indefinitely.

http://www.arti-india.org/index2.php?option=com_content&do_pdf=1&id=45

Post a Comment